Table of Contents

Advantages of General Purpose Semi-Gantry Cranes in Industrial Applications

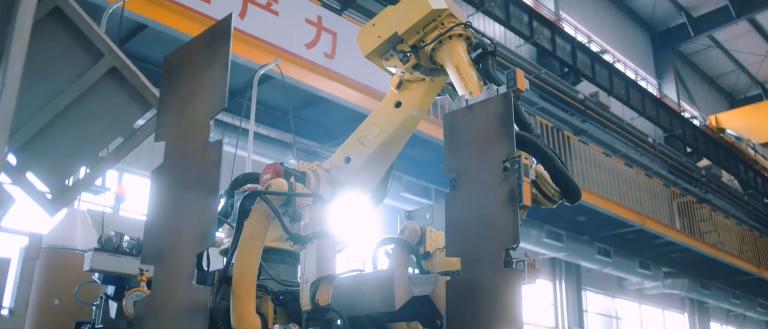

General purpose semi-gantry cranes have emerged as a vital component in various industrial applications, particularly in settings where space constraints and operational flexibility are paramount. These cranes, characterized by their unique design that combines elements of both gantry and overhead cranes, offer a range of advantages that make them an ideal choice for many manufacturing and construction environments. One of the most significant benefits of semi-gantry cranes is their ability to operate in confined spaces. Unlike traditional gantry cranes, which require extensive overhead clearance, semi-gantry cranes can be utilized in areas with limited vertical space, thereby maximizing the use of available facilities. This feature is particularly advantageous in warehouses and factories where height restrictions may hinder the installation of larger equipment.

Moreover, the versatility of semi-gantry cranes cannot be overstated. They can be easily adapted to accommodate various lifting tasks, making them suitable for a wide array of applications, from lifting heavy machinery to transporting materials across a production line. This adaptability is further enhanced by the ability to customize the crane’s specifications, such as load capacity and span, to meet the specific needs of different industries. As a result, businesses can invest in a single piece of equipment that serves multiple functions, ultimately leading to cost savings and increased operational efficiency.

| Nr. | Product Name |

| 1 | LDY metallurgical electric single beam crane |

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In addition to their versatility, semi-gantry cranes are designed with safety in mind. The stability provided by their unique structure helps to minimize the risk of tipping or swaying during operation, which is crucial when handling heavy loads. Furthermore, many manufacturers incorporate advanced safety features, such as overload protection systems and emergency stop buttons, to ensure that operators can work confidently and securely. This focus on safety not only protects the workforce but also safeguards valuable equipment and materials, thereby reducing the likelihood of costly accidents and downtime.

Another notable advantage of general purpose semi-gantry cranes is their ease of installation and maintenance. Compared to traditional overhead cranes, which often require complex installation processes and extensive infrastructure modifications, semi-gantry cranes can be set up relatively quickly and with minimal disruption to existing operations. This ease of installation is particularly beneficial for businesses looking to enhance their lifting capabilities without undergoing significant renovations. Additionally, the maintenance of semi-gantry cranes is generally straightforward, as many components are easily accessible, allowing for routine inspections and repairs to be conducted efficiently.

Furthermore, the economic benefits associated with semi-gantry cranes are significant. Their ability to improve workflow and productivity can lead to enhanced operational efficiency, which translates into increased profitability for businesses. By streamlining material handling processes and reducing the time required for lifting and transporting loads, companies can optimize their operations and better meet production targets. This efficiency is particularly crucial in today\\u2019s competitive industrial landscape, where businesses must continually seek ways to improve their bottom line.

In conclusion, the advantages of general purpose semi-gantry cranes in industrial applications are manifold. Their ability to operate in confined spaces, versatility in handling various tasks, emphasis on safety, ease of installation and maintenance, and economic benefits make them an invaluable asset for many industries. As businesses continue to evolve and adapt to changing demands, the role of semi-gantry cranes will undoubtedly become increasingly prominent, solidifying their status as a preferred choice for efficient and effective material handling solutions.

Choosing the Right General Purpose Semi-Gantry Crane from China’s Best Manufacturers

When it comes to selecting a general purpose semi-gantry crane, the options available from China’s best manufacturers are both diverse and impressive. These cranes are designed to provide flexibility and efficiency in various industrial applications, making them a popular choice for businesses looking to enhance their material handling capabilities. However, choosing the right semi-gantry crane requires careful consideration of several factors to ensure that it meets the specific needs of your operations.

First and foremost, it is essential to assess the load capacity required for your operations. Different manufacturers offer semi-gantry cranes with varying load capacities, ranging from a few tons to several hundred tons. Understanding the maximum weight that the crane will need to lift is crucial, as it directly influences the design and specifications of the crane. Additionally, it is important to consider the frequency of use and the types of materials being handled, as these factors can impact the overall performance and longevity of the crane.

In addition to load capacity, the height and span of the crane are critical dimensions that must be evaluated. The height refers to the maximum lifting height of the crane, while the span indicates the distance between the legs of the gantry. Depending on the layout of your facility and the specific tasks the crane will perform, these dimensions can significantly affect operational efficiency. Therefore, it is advisable to work closely with manufacturers to customize the crane’s specifications to fit your unique requirements.

Moreover, the choice of materials and construction quality is paramount when selecting a semi-gantry crane. Reputable manufacturers in China utilize high-grade steel and advanced manufacturing techniques to ensure durability and reliability. It is beneficial to inquire about the materials used in the crane’s construction, as well as any certifications or quality assurance processes that the manufacturer adheres to. This information can provide valuable insight into the crane’s performance and maintenance needs over time.

Furthermore, the technological features integrated into the crane can enhance its functionality and ease of use. Many modern semi-gantry cranes come equipped with advanced control systems, safety features, and automation options. These innovations not only improve operational efficiency but also contribute to a safer working environment. Therefore, it is advisable to explore the technological offerings of different manufacturers and consider how these features align with your operational goals.

Another important aspect to consider is the manufacturer’s reputation and after-sales support. A reliable manufacturer will not only provide high-quality products but also offer comprehensive support services, including installation, maintenance, and training. Researching customer reviews and testimonials can provide valuable insights into the manufacturer’s reliability and the quality of their customer service. Establishing a good relationship with the manufacturer can also facilitate smoother communication and support throughout the lifespan of the crane.

In conclusion, choosing the right general purpose semi-gantry crane from China’s best manufacturers involves a thorough evaluation of load capacity, dimensions, materials, technological features, and manufacturer reputation. By taking the time to assess these factors, businesses can ensure that they select a crane that not only meets their immediate needs but also supports their long-term operational goals. Ultimately, investing in a high-quality semi-gantry crane can lead to significant improvements in productivity and efficiency, making it a worthwhile consideration for any industrial operation.